Magnesium-Based Alloys for Solid-State Hydrogen Storage

MBN has developed advanced magnesium-based alloys and composites for solid-state hydrogen storage, using its proprietary Mechanomade® process to overcome the challenges of handling highly reactive and ductile magnesium.

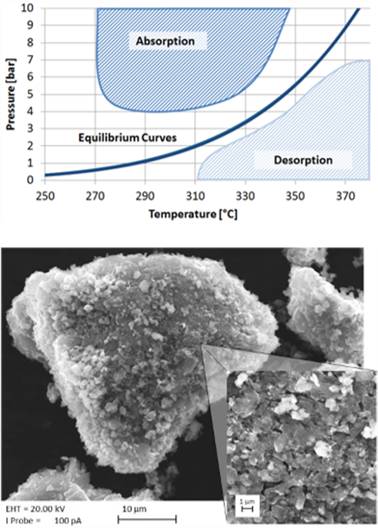

Through mechanical alloying, Mg alloys are synthesized directly in powder form with a refined nanostructure that accelerates hydrogen diffusion along grain boundaries. Nano-oxide catalysts are dispersed during milling, promoting the dissociation of H₂ into atomic hydrogen. This catalytic effect significantly enhances storage capacity, absorption/desorption kinetics, and reduces activation times.

PROPERTIES

GRAVIMETRIC CAPACITY [ 7.1 wt% H₂ | 2.4 kWh/kg ]

VOLUMETRIC CAPACITY [ 0.13 kg H₂/l | 4.4 kWh/l ]

OPERATING TEMPERATURE [ 320 °C ]

DESORPTION RATE [ > 1 g H₂/min ]

This platform enables safer, lighter, and more efficient hydrogen storage, supporting next-generation clean energy systems and accelerating the adoption of hydrogen as a sustainable energy carrier.

MBN has developed advanced magnesium-based alloys and composites for solid-state hydrogen storage, using its proprietary Mechanomade® process to overcome the challenges of handling highly reactive and ductile magnesium.